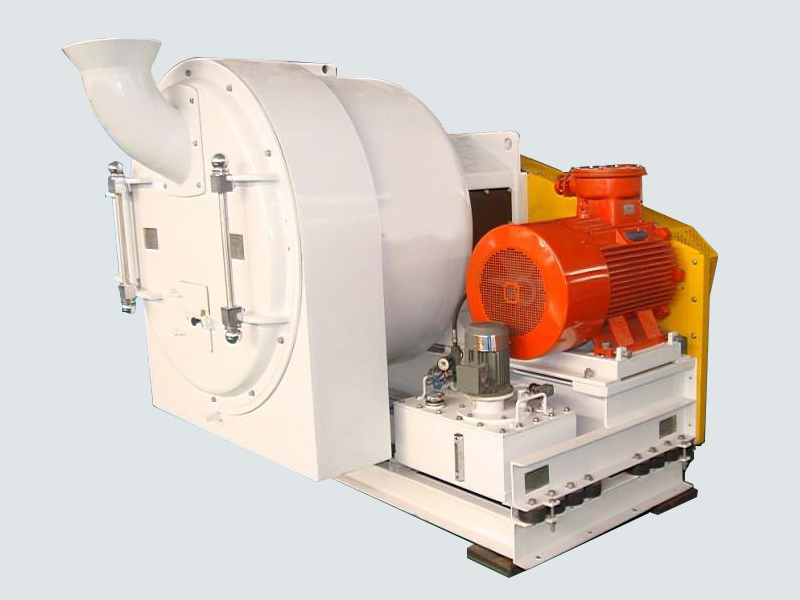

Energy saving mud pump

The special pump for feeding hydraulic piston filter press is characterized by energy saving, large flow, large pressure, no leakage, and extremely low maintenance frequency. It is especially suitable for printing and dyeing plants, leather plants, paper mills, and municipal sewage treatment plants

Keyword:

Category:

Energy-saving mud pump

Hotline:

Energy saving mud pump: special pump for feeding hydraulic piston filter press, characterized by 1. energy saving! Compared with the slurry pump, screw pump and other traditional filter press feed pumps, energy saving is 40-70%=. 2. Large flow, large pressure, no leakage, and extremely low maintenance frequency are especially applicable to: printing and dyeing plants, leather plants, paper mills, and municipal sewage treatment plants. Also known as: hydraulic piston type mud filter press booster pump, special energy-saving mud pump for filter press feeding, energy-saving filter press piston pump, energy-saving hydraulic piston pump, energy-saving piston filter press pump.

Typical applications:

Sludge treatment

1. The sludge receiving bin of the sludge treatment plant receives the municipal sludge, printing and dyeing sludge, industrial sludge and other sludge transported from abroad and transfers them to the sludge storage bin with a hydraulic sludge plunger pump. The plunger pump under the sludge silo continuously conveys the sludge: sludge drying (paddle dryer, disc dryer, rotary kiln), sludge incineration (cement kiln of the cement plant, incinerator of the power plant, incinerator of the sludge incineration plant) Brick factory sludge brick making, sludge solidification landfill. Achieve sludge treatment: harmless sludge, sludge reduction and sludge recycling!

2. The sludge in the sedimentation tank of the municipal sludge treatment plant is pumped by the filter press plunger pump into the upper filter press for dewatering (horizontal screw centrifuge dewatering, screw stacking machine dewatering); Deep sludge dewatering: feed the high-pressure filter press with a double cylinder sludge plunger pump.

3. The dewatered sludge is transported into the sludge transfer bin, sludge receiving bin and sludge storage bin by the sludge plunger pump;

4. The grid slag of municipal sludge treatment plant is transported into the incinerator by a single plunger pump (single shear valve, punch shear head).

5. The sludge produced in the sewage treatment workshops such as printing and dyeing plants, chemical plants and chemical fiber plants is generally received, stored and loaded with sludge pump system (sludge transfer pump system).

Sludge treatment generally selects S swing tube plunger pump, poppet valve plunger pump and cone valve plunger pump.

Previous

Previous

Energy saving mud pump

Related Products

Online Consultation