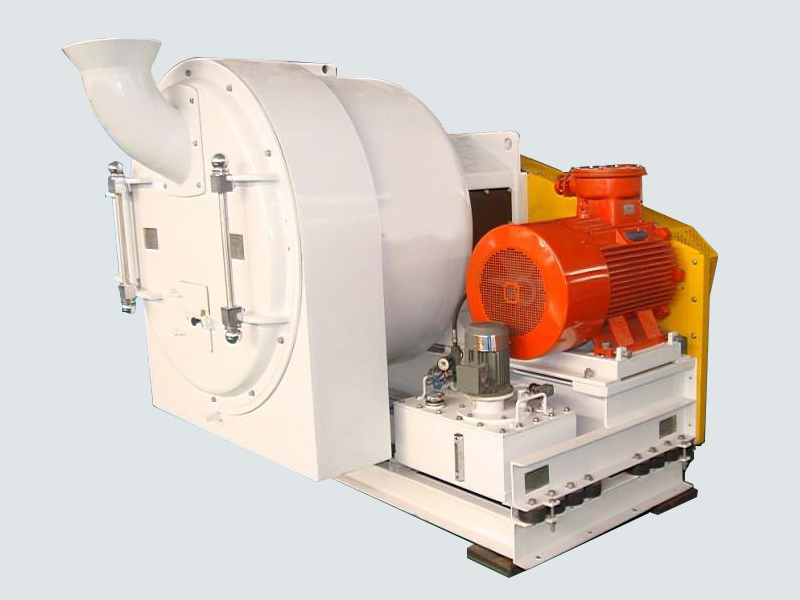

WL1000 horizontal scraper discharge centrifuge

·The horizontal design is more convenient for maintenance than the vertical design, and the whole equipment does not need to be disassembled during horizontal maintenance ·The design of higher centrifugal force (up to 400G) makes the water content of the product lower

Keyword:

Category:

Centrifuge

Hotline:

·The horizontal design is more convenient for maintenance than the vertical design, and the whole equipment does not need to be disassembled during horizontal maintenance

·The design of higher centrifugal force (up to 400G) makes the water content of the product lower

·All drives, gears and bearings shall be kept away from boring areas to avoid material damage to the drive device

·High torque masked gear drive maintains stable speed difference

·The scraper, sieve basket and solid material discharge chamber can be easily seen and accessed through the tall front door

·Independent lubrication system, including necessary monitoring and control instruments, provides oil lubrication for all positions requiring lubrication.

·All parts that may be worn by the product are lined with special ceramic tiles to prolong the service life

·No special foundation required for installation

·Equipment only occupies limited space

·As the discharge of solid materials is completely unimpeded, there will be no blockage in the discharge chute

·The downtime is shortened due to the simplified maintenance and inspection and the design of quick disassembly

·Compared with the vertical slime centrifuge, the capacity is increased by 40% under the same screen basket size and energy consumption

| Processing capacity(t/h) | Diameter of sieve basket(mm) | Feed size(mm) | Product moisture | Main motor(kw) | Oil pump motor(kw) | Overall dimensions(mm) | Weight(kg) |

| 45-65 | 1000 | <=13 | 6%-15% | 75 | 1.1 | 2460×2350×2040 | 3915 |

Previous

TLN1200 vertical slime centrifugal dehydrator

Related Products

Online Consultation