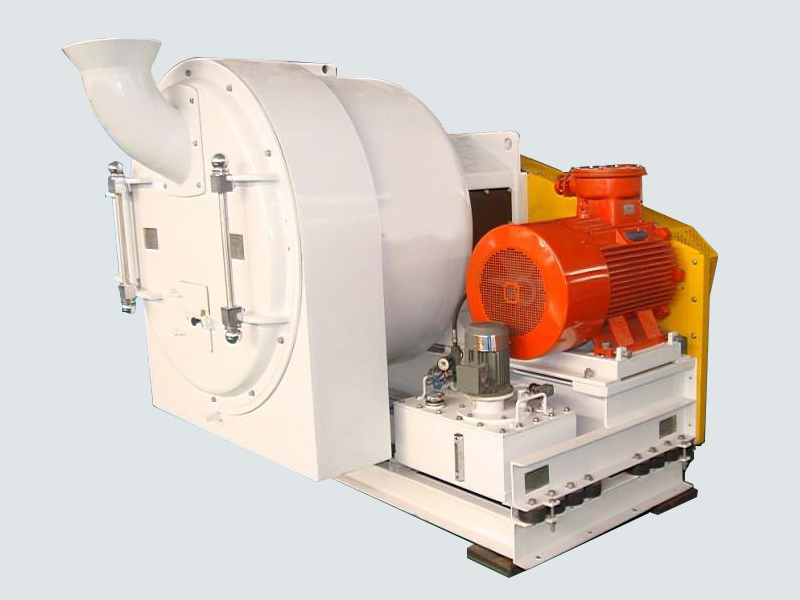

Energy saving mud pump

It has the advantages of wide performance parameters, compact structure, simple maintenance, energy conservation, etc. It is an ideal solid liquid particle conveying equipment for chemical, petroleum, pharmaceutical, printing and dyeing, smelting, paper food and other industries

Keyword:

Category:

Energy-saving mud pump

Hotline:

Mud pump refers to the machinery that delivers mud or water and other flushing fluid to the borehole during drilling. Mud pump is an important part of drilling equipment. In the common positive circulation drilling, the mud pump is used to directly send the surface flushing medium water, mud or polymer flushing fluid under a certain pressure to the bottom of the drill bit through the high-pressure hose, swivel and the central hole of the drill pipe string, so as to cool the drill bit, remove the cut rock cuttings and transport them to the surface. The commonly used mud pump is piston or plunger type. The power machine drives the crankshaft of the pump to rotate, and the crankshaft drives the piston or plunger to and fro in the pump cylinder through the crosshead. Under the alternate action of suction and discharge valves, the purpose of pressing and circulating flushing liquid is realized.

The two main parameters of mud pump performance are displacement and pressure.

The discharge capacity is calculated by discharging several liters per minute, which is related to the borehole diameter and the required return speed of flushing fluid from the bottom of the borehole, that is, the larger the aperture is, the greater the discharge capacity is required. It is required that the upward velocity of the flushing fluid can timely flush the rock cuttings and rock powder cut by the drill bit away from the hole bottom and reliably carry them to the surface. During geological core drilling, the return velocity is generally about 0.4~1.0m/min. The pressure of the pump depends on the depth of the drilling, the resistance of the channel through which the flushing fluid passes, and the nature of the flushing fluid conveyed. The deeper the hole is drilled, the greater the pipeline resistance and the higher the pressure required. With the change of drilling diameter and depth, the displacement of the pump is required to be adjusted at any time. The mechanism of the pump is equipped with a gearbox or its speed is adjusted by a hydraulic motor to change the displacement. In order to accurately grasp the changes of pump pressure and displacement, a flowmeter and pressure gauge shall be installed on the mud pump to enable drilling personnel to understand the operation of the pump at any time, and at the same time, to judge whether the conditions in the hole are normal through pressure changes to prevent accidents in the hole.

Previous

Previous

Energy saving mud pump

Related Products

Online Consultation