Wear resistant pipe elbow

The wear-resistant ceramic composite pipe has rapidly occupied the market. In addition to its high quality and good performance, its performance price ratio is higher than other wear-resistant, corrosion resistant and heat resistant pipes

Keyword:

Category:

Wear-resistant pipe

Hotline:

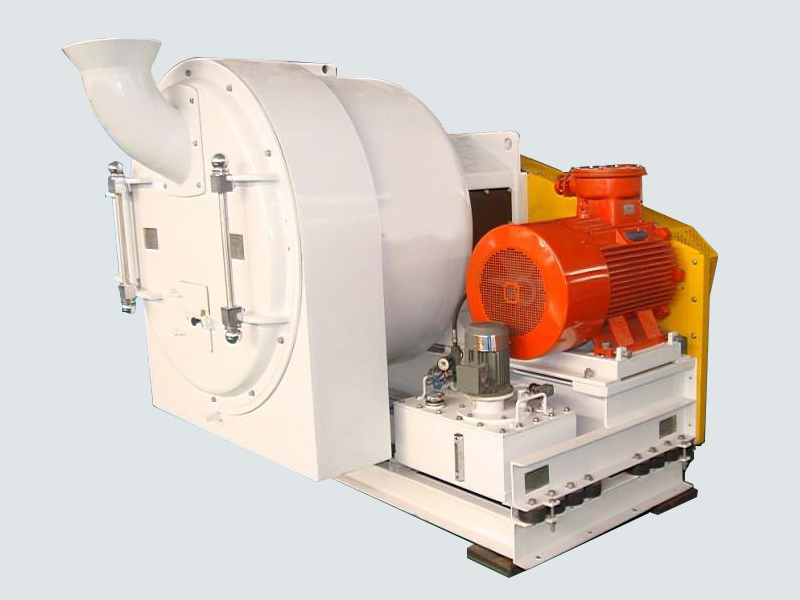

The wear-resistant pipes, namely wear-resistant pipes and wear-resistant pipes, mainly include wear-resistant straight pipes, elbows, tees, reducers, square and round joints, variable diameter pipes and other structural parts, which are mainly used for the transportation of abrasive materials such as pneumatic and pumped slurry. As the transmission medium is generally characterized by high hardness, fast flow rate and large flow rate, and it continuously impacts, abrades and corrodes the pipe wall for a long time during the transmission process, causing the pipe to be worn through gradually due to fatigue.

The wear-resistant ceramic composite pipe has rapidly occupied the market. In addition to its high quality and good performance, its performance price ratio is higher than other wear-resistant, corrosion resistant and heat resistant pipes. In terms of wear-resistant pipes of the same specification and unit length, the weight of wear-resistant ceramic composite pipes is only about half of that of wear-resistant alloy cast steel pipes, and the project cost per meter is reduced by 20% - 30%; Only one-third of the weight of the cast stone pipe, reducing the project cost by 5% - 10% per meter; The price of wear-resistant pipes used in corrosive or high-temperature situations is only a fraction of that of stainless steel pipes and nickel titanium pipes.

In addition to being used for ash removal, slag discharge pipe, powder feeding, powder return pipe and desulfurization pipe in coal-fired power plants, wear-resistant pipes are also used in the following fields:

Coal mine: coal water slurry, coal washing mud, mine filler and coal powder in coal industry;

Metal mines: transportation of concentrates and tailings;

Metallurgy: blast furnace coal injection and slag transportation for iron making in iron and steel plants; CAO, Zibei sand transportation pipeline, steel transportation ferroalloy, furnace refining, etc;

Cement plant: raw slurry transportation, coal powder transportation, elevator feeding, finished cement pneumatic transportation and loading and unloading, concrete transportation, etc. of rotary kiln wet production line;

Chemical plant: coal powder transportation, silicon powder and other raw materials transportation.

Previous

Previous

Rare earth alloy wear-resistant pipe

Related Products

Online Consultation